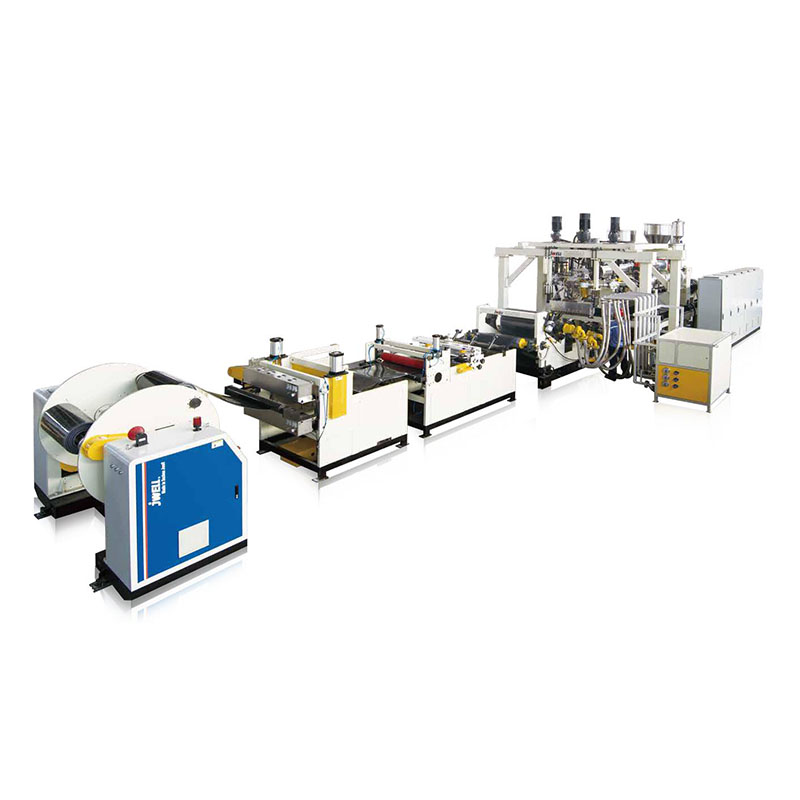

I-PP kunye neCalcium Powder Environmental Protection Sheet Extrusion Line

PP+CaCo3-friendly sheet extrusion line

Iphuhliswe yinkampani yeJwell isebenzisa ii-extruders ezintathu ze-3 okanye i-4 layers co-extrusion. Lo mgca wamkela i-Jwell yamva nje eyilwe PP + CaCo3 vent screw kunye nesixhobo sokulawula ikhompyuter yePLC kunye nesixhobo sokubona ubukhulu ngokuzenzekelayo ukuze umatshini unokunyusa ipesenti yeCaCo3 kwimveliso yephepha ukunciphisa iindleko zeshiti kunye neshiti eliveliswayo. ukufumana iipropathi ezilungileyo zomzimba kunye nezakhono zokuqhubekeka phambili. Ngowona matshini ukwinqanaba eliphezulu eTshayina.

Iinkcukacha eziphambili zobugcisa

|

Umzekelo |

JW-120/100/45-1500 |

|

Ububanzi beemveliso |

1320mm |

|

Iimveliso ubukhulu |

0.3mm |

|

Ulwakhiwo lomaleko |

A/B/C/A |

|

Umthamo |

800kg/h |

Qaphela: Iinkcukacha zinokutshintshwa ngaphandle kwesaziso sangaphambili.

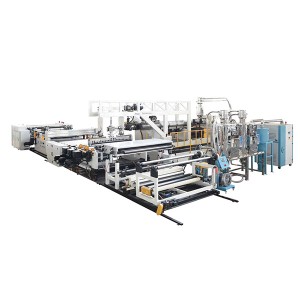

Umboniso weemveliso ezigqityiweyo

Ukuqulunqwa komatshini weplastiki we-extrusion

Umatshini oyintloko womatshini weplastiki we-extrusion yi-extruder, equlethwe yinkqubo ye-extrusion, inkqubo yokuhambisa kunye nenkqubo yokufudumala kunye nokupholisa.

Inkqubo ye-Extrusion

Inkqubo ye-extrusion ibandakanya i-Extruder, inkqubo yokutya, iSkrini sokutshintsha, impompo yokulinganisa, i-T-die. Iplastiki ifakwe kwiplastiki kwi-uniform inyibilika nge-extrusion system, kwaye ngokuqhubekayo ikhutshwe nge-screw phantsi koxinzelelo olusekwe kwinkqubo.

I-Screw kunye ne-Barrel: Yeyona nxalenye ibalulekileyo ye-extruder. Ihambelana ngokuthe ngqo kuluhlu lwesicelo kunye nemveliso ye-extruder. Yenziwe ngamandla aphezulu kunye ne-corrosion resistant alloy steel.I-barrel isebenzisana ne-screw ukuphumeza ukutyumza, ukuthambisa, ukunyibilika, i-plasticizing, i-venting and compacting yeplastiki, kwaye ngokuqhubekayo kwaye ngokufanayo ihambisa irabha kwinkqubo yokubumba.

Inkqubo yokutya: umsebenzi wayo kukuthutha ngokulinganayo iintlobo ezahlukeneyo zeplastiki kwi-hopper ye-extruder.

Umtshintshi wesikrini: Umsebenzi wayo kukususa zonke iintlobo zokungcola kwiplastiki

Impompo yokulinganisa:Ukuxhobisa impompo phambi kwe-extruder, ukujonga uxinzelelo phambi kompompo kunye nokulawula isantya sokukhutshwa, okunokunciphisa i-pulsation kunye nokutya okungaqhelekanga kwezinto eziphathekayo kunye nokuqinisekisa ukuba i-polymer ikhutshwe kakuhle kwaye iqhubeka ihanjiswa kwintloko yokufa. Igobolondo lempompo lithatha umgangatho ophezulu we-alloy-steel kunye

Isixhobo sisebenzisa intsimbi ye-chrome ecinyiweyo okanye ezinye izinto zetsimbi ezikumgangatho ophezulu eziqinisekisa ukusebenza kakuhle kunye nobungqina bokuvuza.

I-T-die: Umsebenzi we-T-die kukuguqula ukunyibilika kweplastiki ejikelezayo kwi-parallel kunye ne-linear movement, eyenziwa ngokulinganayo kwaye ifakwe kakuhle.

Inkqubo yothumelo

Umsebenzi wenkqubo yokuqhuba kukuqhuba i-screw kunye nokubonelela nge-torque kunye nesantya esifunwa yi-screw kwinkqubo ye-extrusion. Ngokuqhelekileyo iqulethe i-motor, i-reducer kunye ne-bearing.

Isixhobo sokufudumeza kunye nokupholisa

Ukufudumeza kunye nokupholisa ziimeko eziyimfuneko ukuze inkqubo yeplastiki ye-extrusion yenzeke.

1. I-extruder ngokuqhelekileyo isebenzisa ukufudumeza kombane, okwahlula ukuchasana nokufudumeza kunye nokufudumala kwe-induction. Iphepha lokufudumeza lifakwe emzimbeni, intamo kunye nentloko. Isixhobo sokufudumeza sitshisa iplastiki kwi-cylinder ngaphandle ukunyusa izinga lokushisa ukufikelela kwiqondo lokushisa elifunekayo ekusebenzeni kwenkqubo.

2. Isixhobo sokupholisa i-extruder simiselwe ukuqinisekisa ukuba iplastiki ikwiqondo lobushushu elifunwa yinkqubo. Ngokukodwa, kukukhuphela ngaphandle ubushushu obugqithileyo obuveliswa kukukhuhlana kwe-chear okubangelwa kukujikeleziswa kwesikrufu, ukuze kuthintelwe iqondo lobushushu libe phezulu kakhulu ukwenza iplastiki ibole, igqabhuke, okanye imilo ibenzima. Ukupholisa umgqomo kwahlulwe kwaba ziindidi ezimbini: ukupholisa amanzi kunye nokupholisa umoya. Ngokuqhelekileyo, ii-extruders ezincinci kunye neziphakathi zifanelekile ngakumbi ukupholisa umoya, kwaye ubukhulu obukhulu buninzi bupholile ngamanzi okanye zidibaniswe neendlela ezimbini zokupholisa.